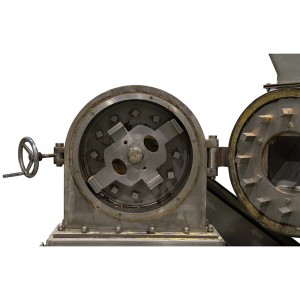

Stainless Steel Food Grinder Machine, Grain spices chili pepper Crushing Machine, Flour Mill Cereal Grinder

Stainless Steel Food Grinder Machine, Grain spices chili pepper Crushing Machine, Flour Mill Cereal Grinder

Preparation before installation, adjustment and use of the machine:

1. The machine can be fixed on the wooden frame, iron frame or cement frame, but it needs to be fixed firmly and the operation is safe.

2. When the grinder and the motor are installed, the two axes are parallel, and the outer end faces of the two belt wheels are on the same plane. The motor installation should have the adjustment gap, the belt tightness adjustment should be appropriate, not too loose or too tight.

3. Powder receiving device: It is necessary to sew a material bag (0.5 m in diameter and 3 m in length). When the material bag is connected to the appropriate aggregate bucket, powder should be produced immediately to realize continuous operation.

4, check whether the bearing grease hardening deterioration, such as hardening deterioration, the application of clean oil wash, replace with new calcium-based grease, and check whether the bolts are loose, if loose should be tightened.

5. After installation, check whether there is any foreign body in the machine, whether the open lock on the pin shaft, cover the machine cover and tighten the handwheel; Use the hand to rotate the belt pulley, rotation should be flexible, no friction or collision phenomenon, and check whether the power steering is correct.

Product advantages:

The working principle of stainless steel crusher is to use high speed rotating gear plate to break the material. It has the characteristics of simple structure, strong versatility, high productivity and safe use.

1, can process food, medicine, chemical and other materials.

2, the processed particle fineness can reach 10-120 mesh arbitrary adjustment.

3, made of 304 stainless steel, to meet the requirements of food grade

Scope of application:

Widely used in food, feed, wine, food, chemical and other industries, is the ideal equipment for material crushing processing.

| Serial number | Model number | Ring diameter | power | Rotational speed | capacity | Overall dimension |

| (mm) | (kw) | (rmp) | (KG/h) | (mm) | ||

| 1 | 200 | 200 | 3 | 7200 | 10-100 | 700*400*980 |

| 2 | 300 | 295 | 4 | 5700 | 30-200 | 850*520*1220 |

| 3 | 400 | 370 | 7.5 | 4500 | 60-400 | 1150*850*1250 |

| 4 | 500 | 430 | 11 | 3900 | 100-600 | 1200*950*1300 |

| 5 | 600 | 510 | 15 | 3200 | 200-900 | 1250*950*1350 |

| 6 | 800 | 650 | 22 | 2800 | 300-1200 |

Products Categories

More...- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur