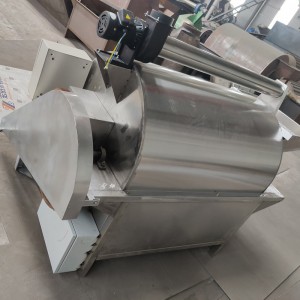

Gas Electric Heating Rotatory Drum Grain Soybean Almond Chestnut Nut Peanut Roaster Roasting Machine can customized service

Gas Electric Heating Rotatory Drum Grain Soybean Almond Chestnut Nut Peanut Roaster Roasting Machine can customized service

| Model number | capacity | weight | Overall dimension |

| (KG/h) | (KG) | (mm) | |

| 80 | 40 | 160 | 1700*1100*1250 |

| 200 | 240 | 220 | 1900*1300*1400 |

Heating method:

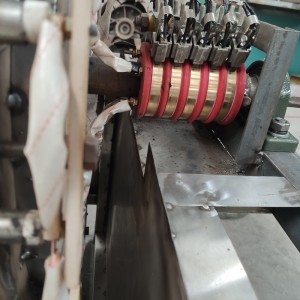

The machine can choose electric heating and natural gas heating two ways.

Scope of application:

Roller roaster is mainly used for beans, nuts, nuts and other products to reduce moisture drying, baking and cooking, the specific products are: walnuts, peanuts (peanuts), hazelnuts, almonds (shell apricots), pine nuts, pistachios, cashews, sunflower seeds, pumpkin seeds, various sunflower seeds, chestnuts, Torreya, raisins, lotus seeds, red dates and other agricultural products. Product advantages:

1, simple operation, small footprint, high efficiency, suitable for small and medium-sized food processing enterprises. In order to adapt to the needs of different scale enterprises, there are a variety of different models of roller baking machine, if there are special needs can also be customized according to actual needs.

2. It is particularly important to observe the stability and color of dried products when baking. The machine has a wide range of materials, simple operation, small maintenance and stable quality of dried products.

Maintenance tips:

1. Before starting the machine, check and maintain the main transmission parts: bearings, triangle belts or conveyor belts are damaged or damaged in use, which should be repaired or replaced in time.

2, in outdoor work, to take the corresponding protective measures, need to carry out a comprehensive maintenance every year, every two years need to carry out a paint protection.

3, if not for a long time, to clean up the internal and external debris, speed regulating motor speed meter should be returned to zero standby.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur